Tel : +8613285927168 Email : sales@molibon.com

-

Email : sales@molibon.com

-

Phone : +8613285927168

Email : sales@molibon.com

Phone : +8613285927168

Tel : +8613285927168 Email : sales@molibon.com

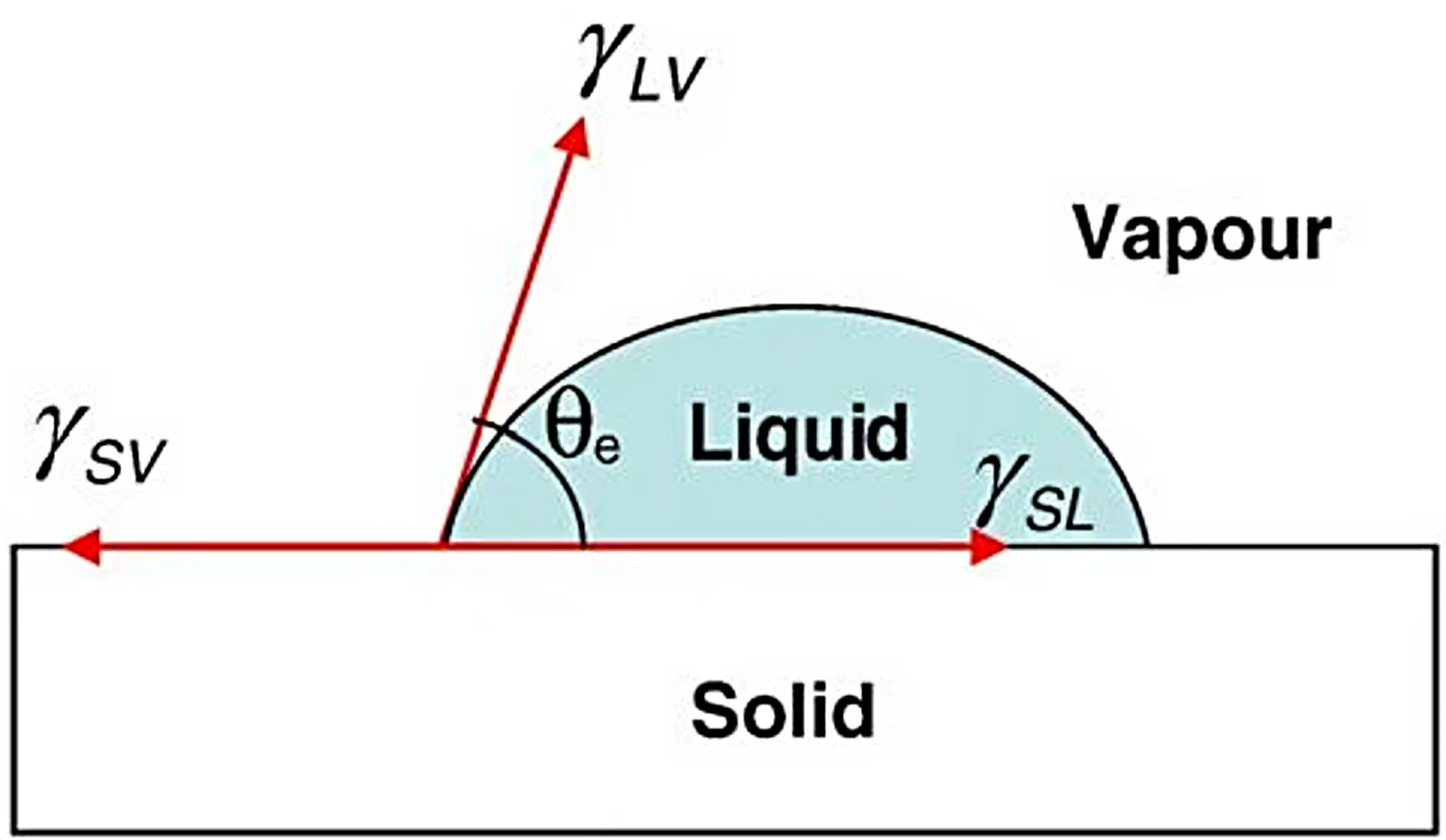

Surface energy, typically measured in millinewtons per meter (mN/m), quantifies the excess energy at a material's surface compared to its bulk. This arises from the asymmetric bonding environment of surface atoms, which experience fewer interactions than atoms within the material.

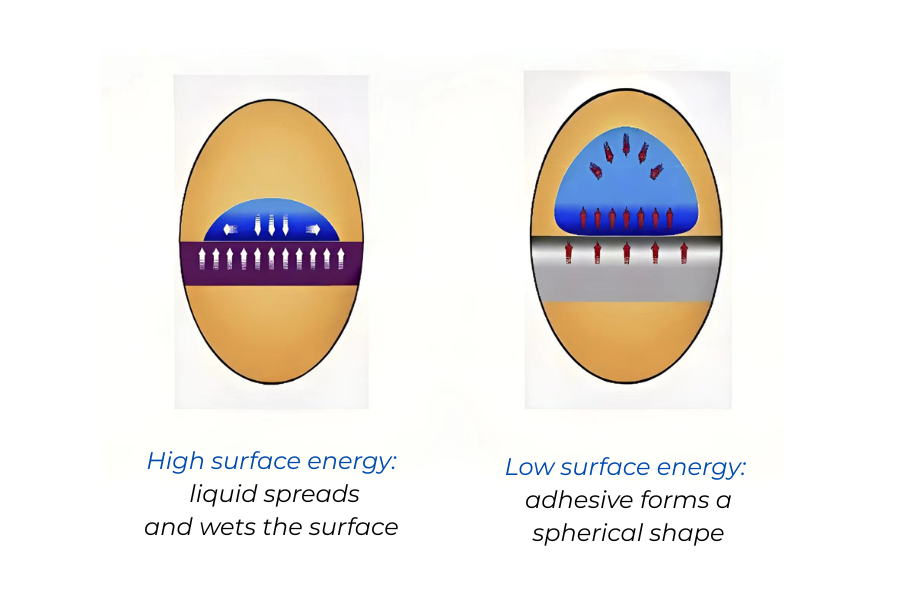

Low surface energy materials exhibit high contact angles and poor liquid spreading due to their low surface tension. In contrast, high surface energy materials (like glass and metals) promote wetting and yield low contact angles, as liquids spread easily to adsorb on the active surface.

Why It's Hard to Glue Low Surface Energy (LSE) Surfaces?

The bonding process consists of two critical stages: : First, the LSE glue must spread across the entire surface. Second, it must establish intimate, molecular-level contact with the surface. We call this process "wetting."

How well a structural adhesive can spread and "wet" a surface depends on a few key things. A good bond happens when both the structural bonding adhesive and the surface are capable of similar types of molecular attraction.

Low surface energy surfaces tend to have poor wettability, resulting in a large contact angle. This happens because the surface can't form strong bonds, making it hard for liquids to break the molecular bonds and interact with the surface. Common low-energy surfaces include hydrocarbons. Their molecules have very little attraction to other substances.

On the other hand, High surface energy materials (like glass, ceramics, and metals) are easy to wet, leading to a low contact angle. Their surfaces strongly attract liquids, causing them to spread out.

Low Surface Energy Structural Adhesives

Although a wide range of adhesives exists for bonding common materials like metals, paints, and plastics—including structural, non-structural, and pressure-sensitive types—these conventional options have historically failed on thermoplastics like TPO due to their unique surface properties.

Bonding Low-Surface-Energy (LSE) materials like polypropylene (PP) or 6061 aluminum can be difficult. Molibon's low surface energy adhesive are formulated to solve this, creating strong bonds on a wide range of LSE plastics and metals without requiring surface preparation. Easy to use from a standard cartridge, the impact resistant structural adhesive provides durable performance for applications ranging from new energy equipment and industrial machinery to electronic device casings and multi-material assemblies.

Leave A Message

Scan to Wechat :