Tel : +8613285927168 Email : sales@molibon.com

-

Email : sales@molibon.com

-

Phone : +8613285927168

Email : sales@molibon.com

Phone : +8613285927168

Tel : +8613285927168 Email : sales@molibon.com

Although both SMC and FRP are composite materials widely used in industry, they are actually quite distinct. What are their main differences? This article breaks it down in four simple parts: their composition, manufacturing processes, typical uses, and cost differences.

1.Composition:

SMC: Sheet Molding Compound is a premixed dry molding compound made of unsaturated polyester resin, chopped glass fiber, and filler through impregnation and compaction into sheet material.

FRP: Fiber Reinforced Plastic is a composite material using glass fiber or its products as reinforcement and synthetic resin as the matrix material.

2.Manufacturing Process:

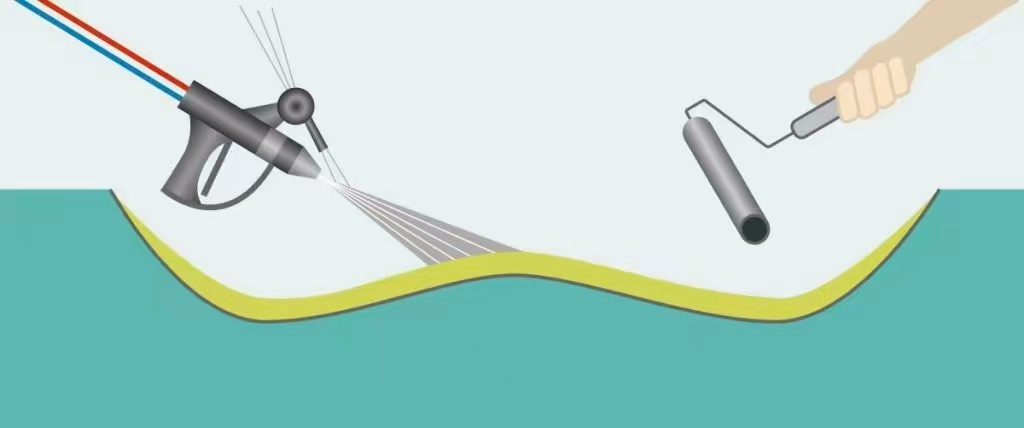

SMC: It must be formed using a method called compression molding. This process requires both high pressure and high heat, typically around 130–150°C.

Fiberglass: It can be made in many ways. These include techniques like hand lay-up, spray-up, pultrusion, filament winding and also compression molding.

3. Applications:

SMC: Widely used in automotive parts (like bumpers and doors), housings for electrical equipment, and components for construction.

FRP: It is commonly used to make parts and structures like pipes, storage tanks, boat hulls, cooling towers, amusement park rides, and sports equipment.

4. Cost:

SMC: Generally more expensive, suitable for high-volume, high-precision products.

Fiberglass: Relatively cheaper, suitable for small-volume or large, irregularly shaped products.

For bonding these two materials, we recommend Molibon's polyurethane plastic glue PU-7456.

Benefits:

(1) Eco-Friendly Formula:The premium urethane structural adhesive is solvent-free without formaldehyde or benzene.

(2) Easy Application: Excellent anti-sag properties with a 1:1 mixing ratio. Working time: 15–20 minutes. Initial curing time: 60–120 minutes.

(3) Mechanical Properties: The fast-curing polyurethane plastic adhesive offers excellent strength and flexibility. Key specs include:

• Shear Strength: ≥8 MPa

• Elongation at Break: ≥60%

• Hardness: ≥60 Shore D

(4) Weather Resistance:Built for durability, the structural plastic adhesive resists water, corrosion, and damp-heat aging to maintain high performance in harsh conditions over time.

SMC and FRP are high-performance composites widely used in automotive and construction. Molibon PU-7456 polyurethane bonding adhesive offers an ideal solution for bonding SMC and FRP, it excels in structural applications requiring impact resistance and weather durability.

Leave A Message

Scan to Wechat :