Tel : +8613285927168 Email : sales@molibon.com

-

Email : sales@molibon.com

-

Phone : +8613285927168

Email : sales@molibon.com

Phone : +8613285927168

Tel : +8613285927168 Email : sales@molibon.com

The quality of glue ingredients is fundamental to both product safety and lifespan.This makes ingredient analysis and testing a critical step. This article explains the standards for testing glue ingredients—focusing on Molibon's specially developed acrylic structural adhesive.

I. Physical Performance Testing Standards

1.Viscosity: Viscosity is a key measure of a glue's flowability and is expressed in Pascal-seconds (Pa·s). The two parts of Molibon MA-5235 polycarbonate adhesive have different viscosities at 24°C. Part B (200-300 Pa·s) is notably thicker than Part A (100-250 Pa·s).

2.Curing time: Curing time means how long the glue needs to cure. This standard directly impacts its application and effectiveness. For our MA-5235 polycarbonate sheet glue, this takes 15-25 minutes at 24°C.

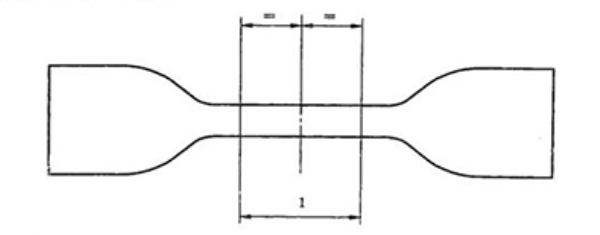

3.Tensile Strength: Tensile Strength measures the maximum pulling force a cured glue can withstand, as tested on a standard "dumbbell" shaped sample. For Molibon MA-5235 polycarbonate glue, after curing for 24 hours, the tensile strength exceeds 25.4 MPa. Practically, this means a 1 cm² bond can support over 10 kg.

II. Chemical Performance Testing Standards

1.Component Analysis: This test identifies all the ingredients in the glue and measures their exact amounts. This ensures the formula is correct and consistent.

2.PH Value: Measuring pH values can determine the chemical stabilityof adhesives. It ensures that the adhesive remains stable over time and will not damage materials such as metal, plastic or wood.

3.VOC Content: VOCs are harmful chemicals that can evaporate into the air. Molibon strictly limit their amount in our structural bonding adhesive to meet environmental regulations.

Leave A Message

Scan to Wechat :