Tel : +8613285927168 Email : sales@molibon.com

-

Email : sales@molibon.com

-

Phone : +8613285927168

Email : sales@molibon.com

Phone : +8613285927168

Tel : +8613285927168 Email : sales@molibon.com

As a new interior decoration material derived from the ceramic industry, sintered stone slabs fundamentally differ from traditional tiles in their application scenarios and workability. This article will detail the four steps for seamless 45° jointing of sintered stone slabs, utilizing Molibon's proprietary joint adhesive:

1. 45° Cutting

In practical applications, stone slabs (Marble, Granite, Sintered Stone, Solid Surface) are often used for right-angle applications, such as bathtubs, washbasins, center islands, and cabinet corners. These applications often require a 45° cut.

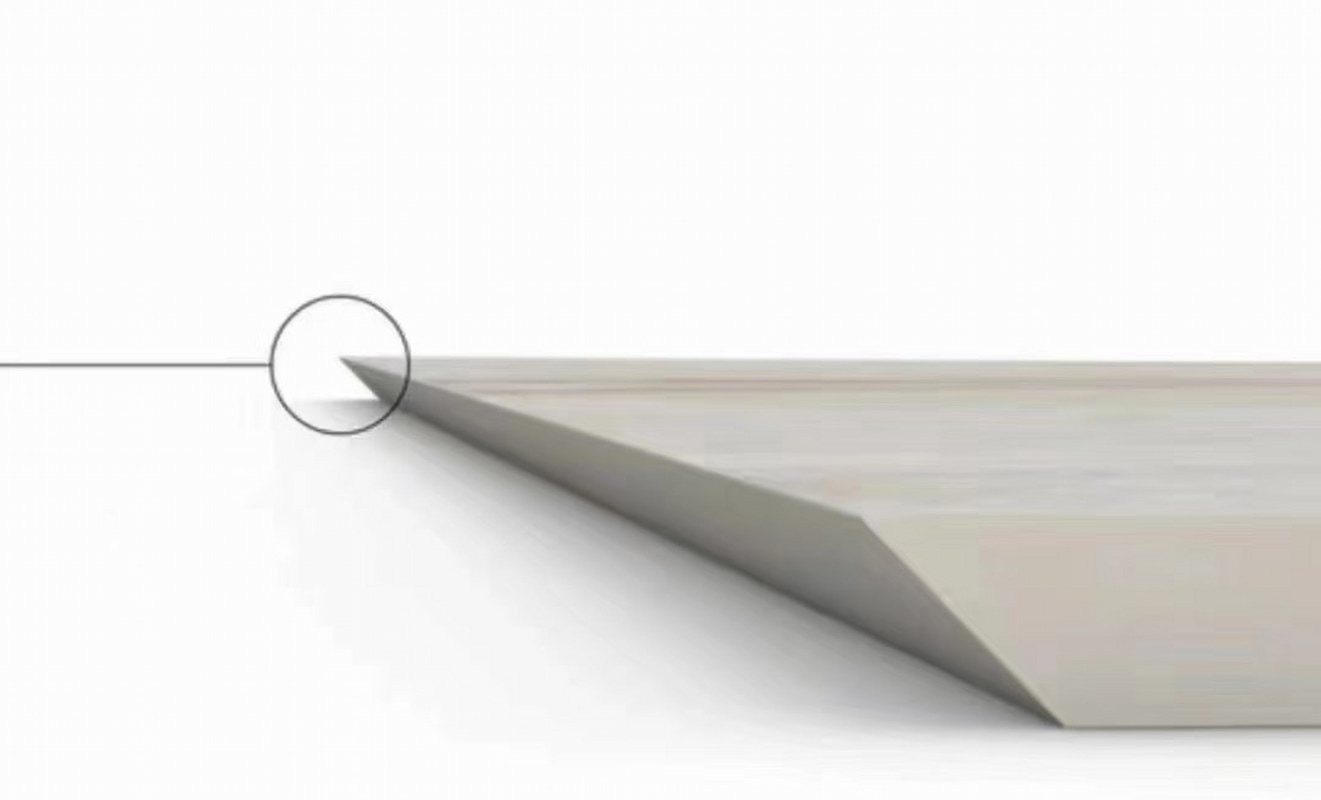

Similarly, a 45° cut in a stone slab requires precise angles and a smooth, even cut. Processing precision determines the quality of the finished product. A smooth cut and flawless, aesthetically pleasing joints ensure a truly seamless joint.

2. Treatment Before and After Joining

Seamless joining refers to a 45° chamfer that forms a sharp angle with the glaze surface, leaving no margin for the corner.

Because edge grinding is performed by machine, some imperfections are inevitable. Therefore, a second manual grinding and inspection is required after edge grinding to ensure the quality of the finished product.

3. Gluing

Before using Molibon's professional epoxy stone glue for seamless joints, we need to perform some preparations:

1) Clean the slabs and allow them to dry completely;

2) Verify the dimensions and quality of the drawings

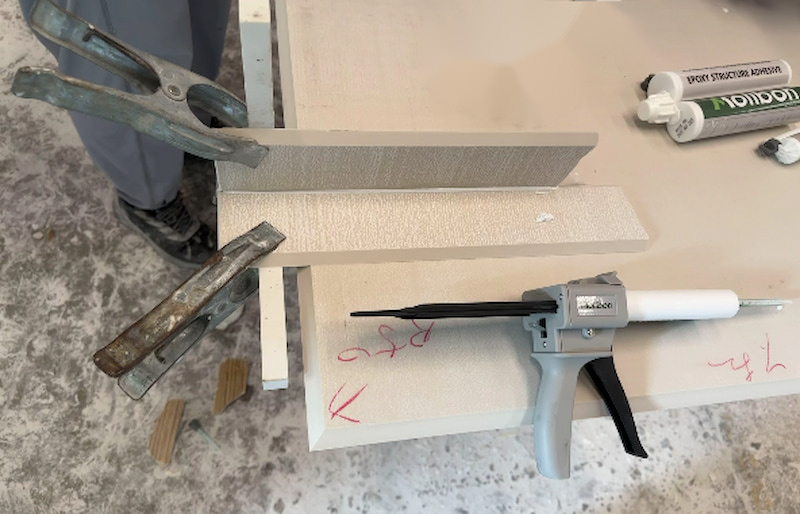

3) Position the slabs to be joined and apply the special glue to the 45-degree joint.

4) Use a right-angle clamp to secure the slabs together to ensure a straight, beautiful finish.

5) Allow to stand for 3-5 minutes. If the glue is not completely dry, any excess glue will need to be cleaned up.

4. Surface Preparation

After the glue has dried for 20-30 minutes, use a sponge, angle grinder, or sandpaper to remove any excess glue. (Note: Always use the sponge or angle grinder at a 45-degree angle.) When the grinding disc makes a snapping sound, the glue has been smoothed out.

IMPORTANT:

Stop sanding if you hear a snapping sound, as this will damage the glaze and ruin the appearance. Finally, scrape off any excess glue with a blade. Once the glue is removed, polish with a grinding disc of at least 1000#.

Using Molibon glue series(Acrylic Solid Surface Joint Glue, Epoxy Stone Glue), combined with the standard 45° seamless splicing process, can greatly improve the splicing strength and aesthetics. It is suitable for a variety of scenarios such as high-end sintered stone countertops, marble countertops, solid surface special-shaped structures, etc.

Leave A Message

Scan to Wechat :