Tel : +8613285927168 Email : sales@molibon.com

-

Email : sales@molibon.com

-

Phone : +8613285927168

Email : sales@molibon.com

Phone : +8613285927168

Tel : +8613285927168 Email : sales@molibon.com

Epoxy resin adhesives are widely used in industrial production and renovation projects due to their excellent bonding properties and weather resistance. However, shrinkage is a common issue during their use. This article explores what structural epoxy adhesive shrinkage is and how Molibon's formula is engineered to overcome it.

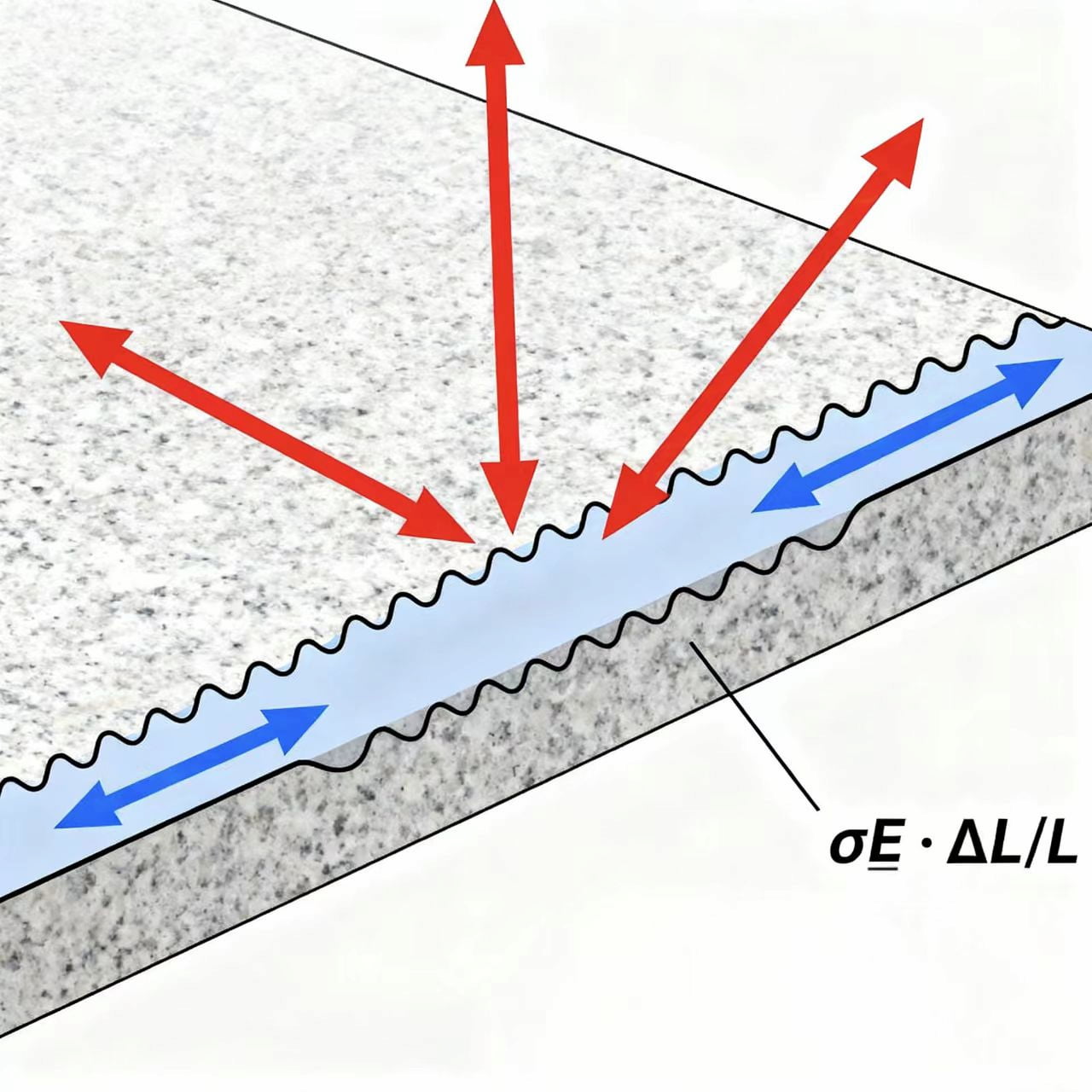

Shrinkage in epoxy adhesives occurs during the curing process. As the epoxy resin and hardener chemically react to form a cross-linked structure, the molecular chains draw closer together. The reduction in molecular distance leads to a contraction of the overall volume.

1.Effects on Bond Strength & Performance

(1). Internal Stress and Cracking: Shrinkage generates stress within the epoxy adhesive glue itself, which can lead to cracking or deformation.

(2). Poor Bonding: If the stone adhesive glue shrinks too much, it may create gaps between the adhesive and the bonding surface. This not only weakens the bond but can also cause the bonding surfaces to debond.

These challenges make shrinkage control an essential part of professional stone engineering.

2.Key Advantage of Molibon Industrial Epoxy Adhesive in Terms of Shrinkage

To address these challenges, Molibon epoxy bond stone adhesive features an optimized formula specifically designed for stone bonding, which effectively alleviates problems caused by shrinkage:

(1). Precision Low-Shrinkage Formula: Molibon chemical stone adhesive uses a precisely balanced resin-to-hardener ratio in a premium formula. This controls volumetric shrinkage to an extremely low range, thereby significantly reducing internal stress and the risk of cracking or deformation.

(2). Exceptional Bond Stability: Due to its low shrinkage rate, Molibon epoxy resin stone glue ensures in timate contact with substrates such as stone and rock slabs after curing, providing long-term stable bonding strength for various stone installation scenarios such as sinks and countertops.

(3). Construction Adaptability: Its shrinkage characteristics match the physical properties of stone. Combined with good fluidity and curing speed, it not only ensures easy application during construction but also maintains the integrity and stability of the bonding parts after curing, balancing both construction efficiency and final bond quality.

3.How to Achieve Even Better Results?

For optimal results with Molibon 2 part epoxy resin glue, follow these tips to reduce shrinkage:

(1). Follow Mixing Ratios Precisely: Incorrect ratios can increase shrinkage and impair cure. Always use the glue gun and mixer that comes with your epoxy bonding adhesive for mixing.

(2). Control Curing Conditions: Keep the curing environment stable — avoid high heat or humidity to reduce shrinkage.

(3). Substrate Treatment: Clean and dry bonding surfaces completely. Remove dust and oil to improve adhesion and reduce shrinkage effects.

Leave A Message

Scan to Wechat :